Revolution in the measurement process: The programmed fixture Flex-Station

In the aviation industry, where precision and efficiency are crucial, measuring complex milled aluminum parts poses a tremendous challenge. Previously, in our customer application for over a thousand differently shaped parts, several specific measuring fixture were needed for each part–an expensive and logistically demanding process. The goal is now to measure all types of workpieces efficiently and repeatably with a single, flexible, and programmable fixture, with minimal setup effort and fully automated.

The challenge: Complexity and cost

The conventional method of using specific measuring fixture for each workpiece not only leads to high costs in design, manufacturing, and logistics but also to a tremendous amount of time. Each workpiece must also usually be measured in at least two positions, further increasing the complexity.

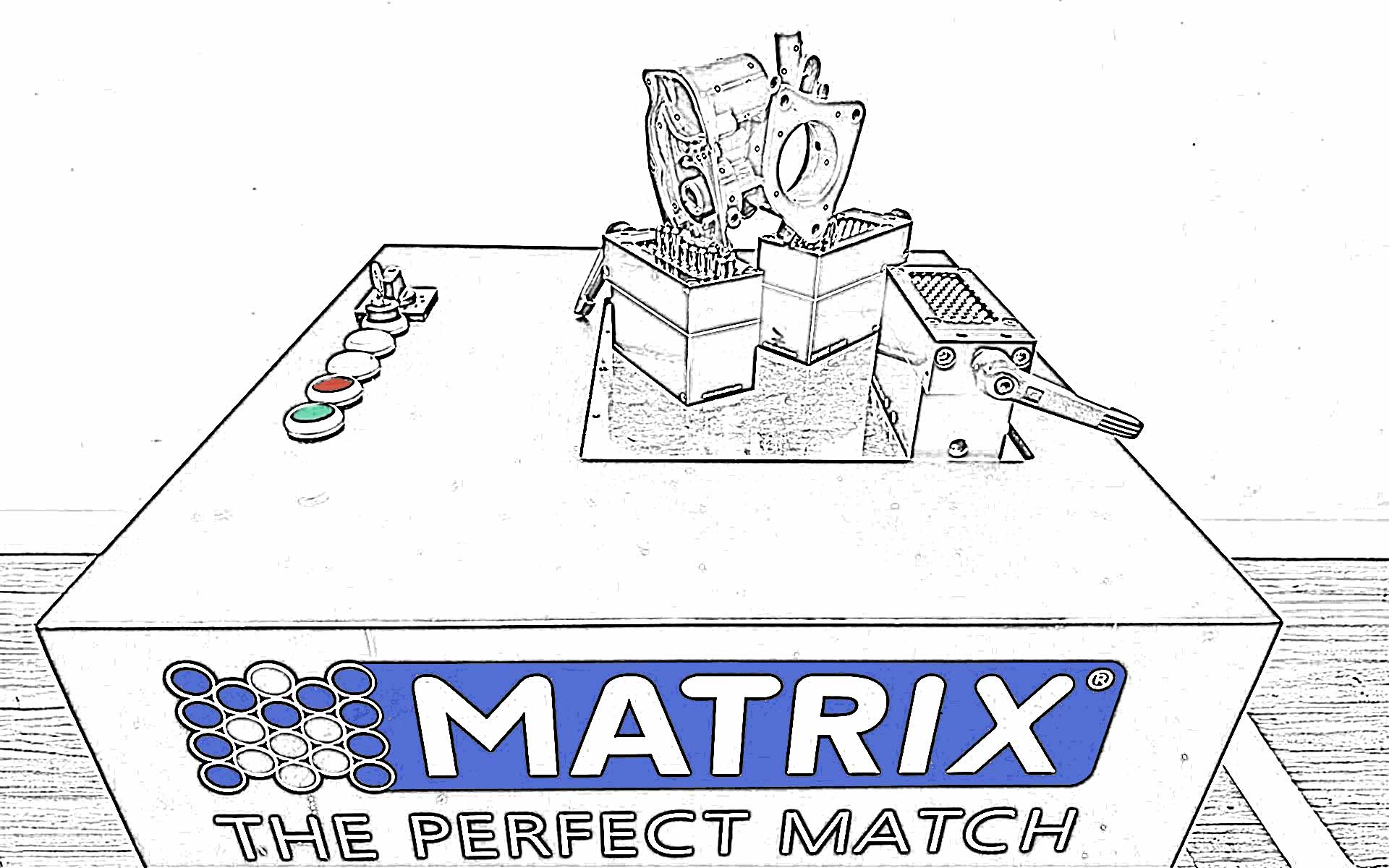

The solution: The Flex-Station by MATRIX

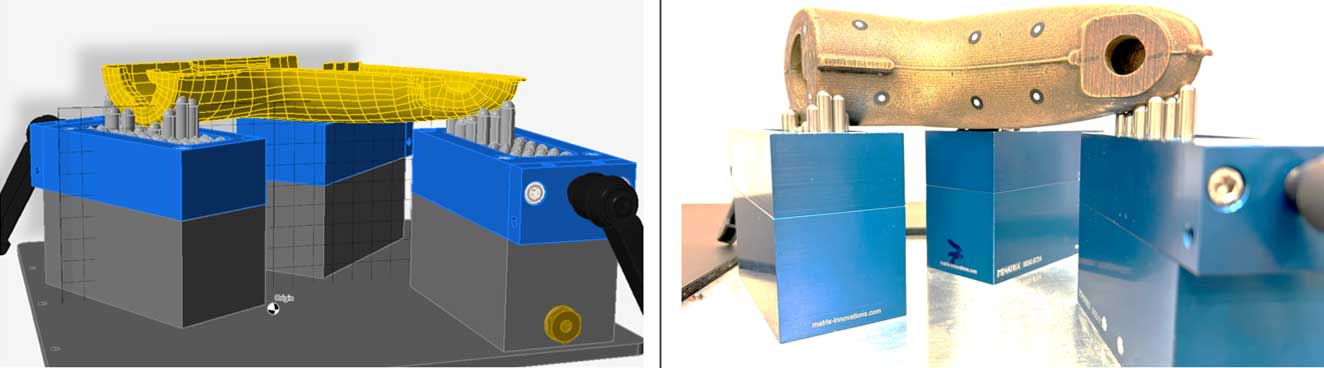

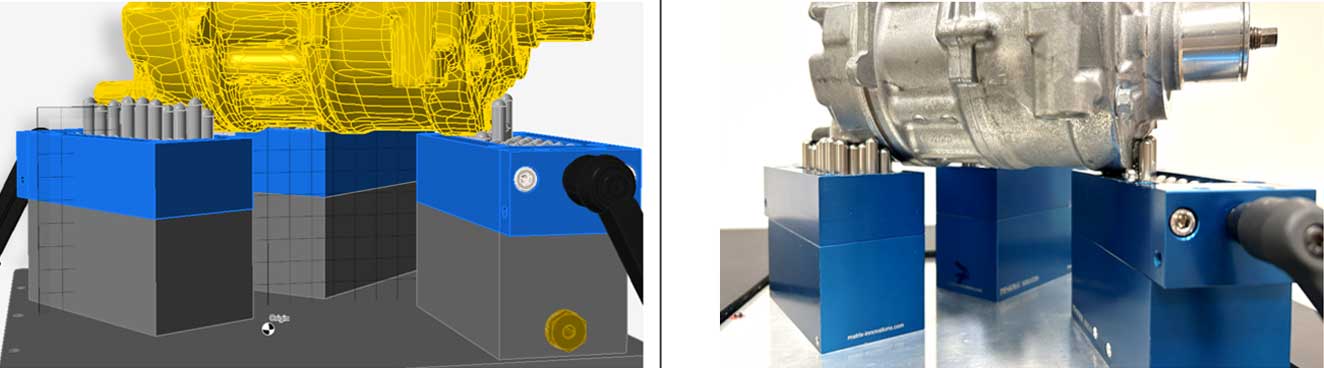

The Flex-Station by MATRIX sets new standards in the field of fixtures and workpiece carriers. Thanks to the advanced MATRIX software, 3D data of the workpieces in formats such as .STP, .STEP, or .STL can be read into the software and positioned on the well-known MATRIX pin modules. The software calculates the pin positions, which are then saved as a program. These programs can be automatically called up and executed by the plant control system, allowing the pins to be set with high precision and repeatability. Subsequently, the created fixture is loaded by a robot.

Benefits and optimizations

With the introduction of the Flex-Station, specific fixtures can be completely replaced. This leads to a significant reduction in personnel costs for the design of specific fixtures and in manufacturing and storage costs. The flexibility and programmability of the fixture minimize the setup effort and maximize efficiency in the measurement process.

Conclusion

The implementation of the Flex-Station in the measurement process of the aviation industry illustrates how process optimizations and cost savings can be achieved through innovative technologies. This technology enables flexible, efficient, and precise measurement of complex workpieces and sets a new standard in the automation of measurement processes.

Extract from MATRIX software