The Flex-Clamp MINI System

In today‘s fast-paced production landscape, efficiency and precision are essential, especially when it comes to handling and assembling small parts. A challenging scenario in this field is the automated assembly of electronic connectors, which come in various shapes and sizes. The task is to automatically pick up these connector housings from a vibrating conveyor and position them precisely in front of an assembly station, which then inserts the cable. A particular challenge here is that a button on the connector must not be pressed during the gripping process.

The Challenge: Diversity and Precision

The variety of connector shapes and sizes presents a significant challenge that requires a flexible and precise solution. Moreover, the gripping system must be able to optically recognize the parts and handle them without damage or malfunction. This requires an innovative solution that can adapt to the different contours of the workpieces without affecting critical components like the mentioned button.

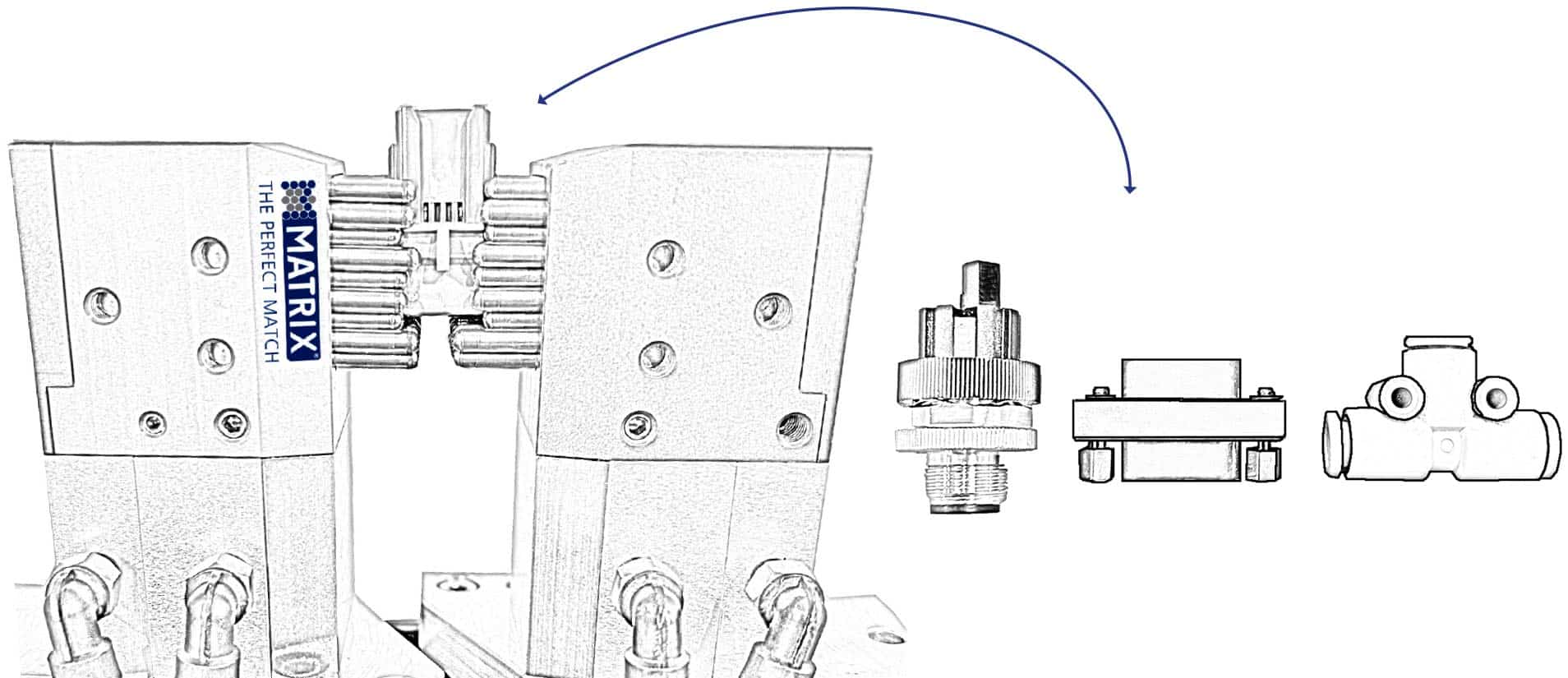

The Solution: Flex-Clamp MINI System

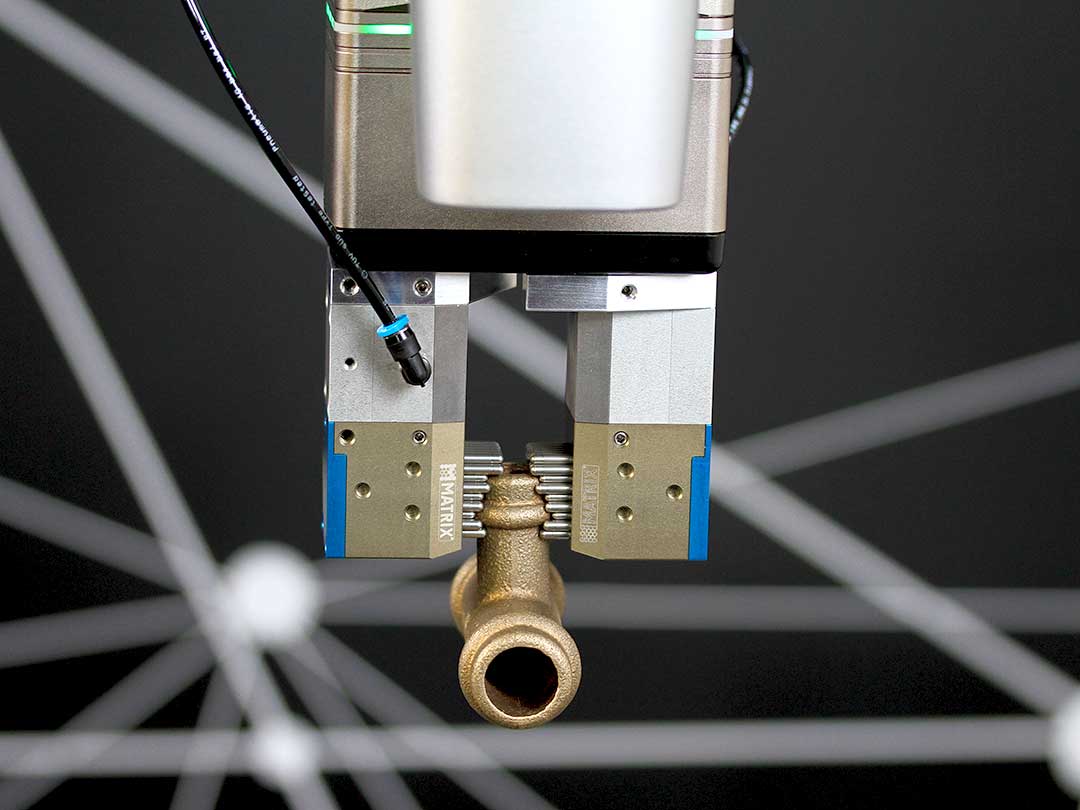

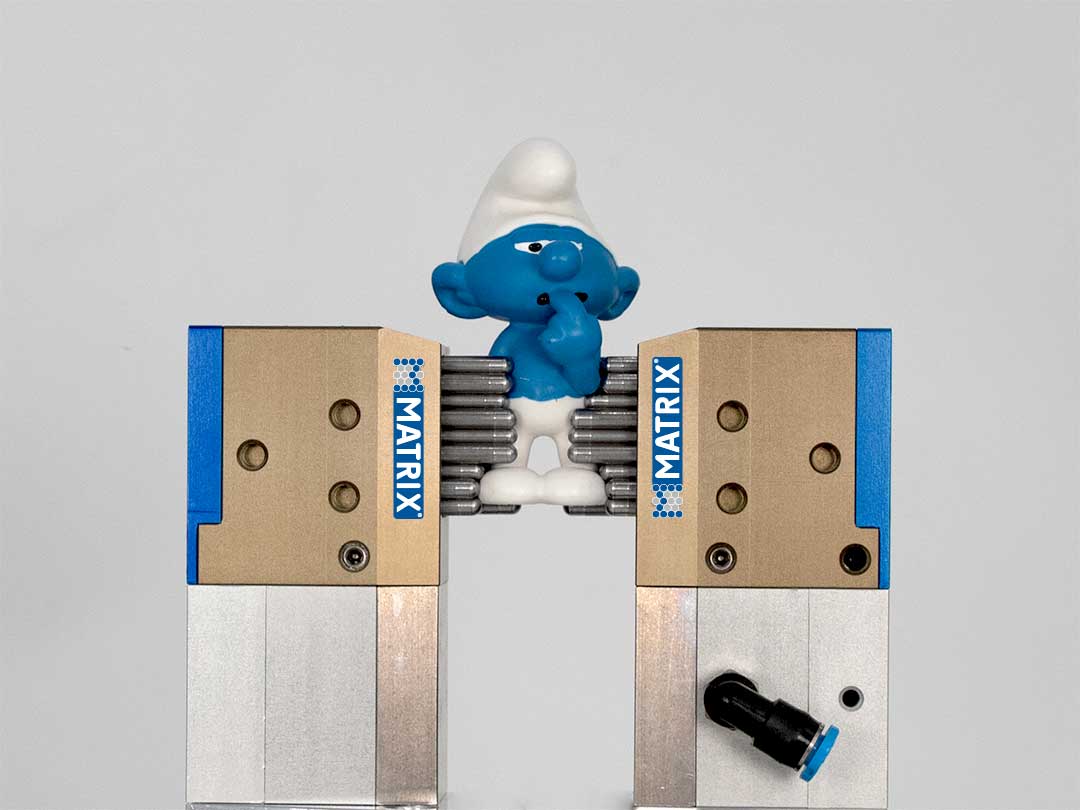

a flexible gripping solution that instantly adapts to any workpiece contour, absorbs forces, and can move parts with repeat accuracy. This system allows for the complete replacement of part-specific gripper jaws, thereby eliminating production downtime due to gripper changes. Such innovation not only saves valuable time but significantly optimizes the entire assembly process of the end customer.

Thanks to the precise form-fit that the Flex-Clamp MINI System enables, a very low gripping force is needed. This is a crucial advantage, as it means the workpieces are not deformed, and critical operating elements on the connectors remain untouched. The system thus guarantees safe and efficient handling of the connector housings, without the risk of damage or accidental pressing of the button.

Conclusion

The Flex-Clamp MINI System by MATRIX® represents a significant advance in robotic gripper technology. It successfully addresses the challenges associated with the diversity and required precision in the automated assembly of electronic connectors. By implementing this system, companies can significantly improve their assembly process, increase efficiency, and boost productivity. It is a shining example of how innovative technologies are driving Industry 4.0 forward and elevating production processes to a new level.